23 October 2014

Make a Vinyl Cabinet

Introduction:

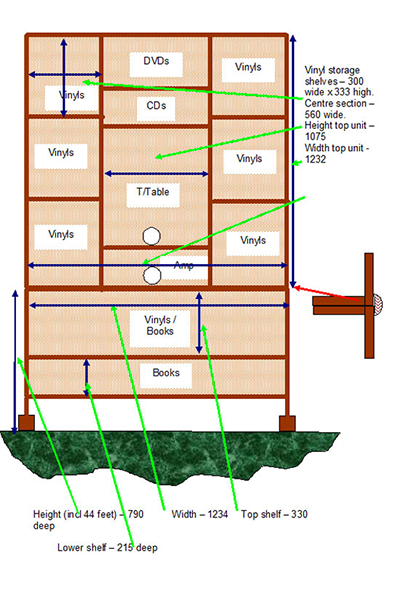

Here’s a cabinet that not only keeps your precious vinyls safe, but also provides space for the turntable, amp, and possibly also assorted DVDs, CDs, books and what-have-you.

The dimensions and materials relate to this unit because it was essentially designed around the turntable and amp, and, of course, the vinyls. You might decide not to include certain storage features – or add some – and amps and turntables come in a variety of sizes, and that will affect the size, dimensions and amount of materials you will require.

Measure units such as turntables etc very carefully and allow adequate space around them for ventilation. Also bear in mind that turntables usually have covers, and when opened, the depth of the unit is greater than when it is closed.

What you will need:

- SA pine:

- 305×19 laminated pine – six 2.4m lengths;

- 32 half round – 6m;

- 700mm of 44×44 – for the feet;

- one full sheet 3mm Masonite – backing;

- wood glue,

- 50mm 8 gauge chipboard screws – bag of 100;

- finish of your choice – I selected a gloss marine varnish.

*All materials are available at Selected Mica Stores. To find your nearest Mica and to enquire about availability, please go to www.mica.co.za, to use our store locator. If your local Mica does not stock exactly what you need they will be able to order or suggest an alternative product or a reputable source.

Method:

- I made the top section first and as always, the golden rule is: measure twice, cut once… cut the sides and, top and base, using the first of each as a template for its mate – so that you get a very precise result – the pieces need to be an exact match as the turntable has to be precisely level if the turntable arm is to track properly.

- I used sample DVDs and CDs, and a scrap LP, to ensure there was room for a finger to get in on top of the required item to pull it out of the shelf.

- And here I am with the CD – same rule as above.

- I built this unit from the inside out… starting with the centre section – the DVD, CD, turntable and amp section. Clamp the unit together and use glue and five 50mm screws per join to secure it.

- I drove the screws in below the wood’s surface.

- Like so. Note the faint line to ensure the screws were dead centre on the shelf and in a neat, straight line. Secure the top first, and then the bottom and then fill in with the remaining three screws.

- If your cutting is really accurate the unit will be that much stronger and more rigid.

- Here’s a hint… when drilling a large number of holes and you want them to line up, make up a marking stick as I did here… you simply space the first screws very accurately, mark their positions along the stick, and then transfer those same marks to the unit when drilling the pilot holes.

- A view of the unit with the top, bottom and sides added; now for the vinyl shelves…

- They fitted in very snugly – see, it pays to be careful with your cutting – and fixed in position, as with the rest of the unit, with glue and five screws per join.

- The assembled top section of the unit, by far the biggest and heaviest. All that needs to be added now is the backing, which was cut to size using a craft knife and then attached using glue and staples to secure it in position. Even without the backing, the unit was very rigid. Don’t forget to add holes in the backing where the turntable and amp go – for the wiring.

- The screw holes were filled with pine filler, left proud of the surrounding surface, and then sanded down flush with the surface.

- The completed unit.

The base unit was a far simpler proposition and took a fraction of the time I had to endure making the top section. I added 32mm half round – see the detail in the diagram – to hide the junction between the top and the base of the unit, and also added it to the very top and very bottom of the unit to give a little embellishment.

Note: As the top section fits on the bottom section, it needs to be ever so slightly narrower than the latter. That is why the lower section is 1234mm wide and the upper section is 1232mm – that gives just 1mm play on either side, but when the two units are in position, the gap is so tiny it looks like they are a single unit.

I added feet to the unit, to make it just that little more stable and for this purpose I used an off-cut of 44×44 SA pine, cut to two lengths of 380mm – that meant the feet (flush with the back of the lower unit) protrude 75mm and help prevent the unit from tipping forward away from the wall. I used glue and three 50mm screws per foot, countersinking them 24mm into the feet so that they have good purchase in the sides of the base unit.

To complete the unit, fill all screw holes and once the filler has set, sand down all surfaces and apply the finish of your choice, as per the manufacturer’s instructions.

The completed unit is great for vinyls and so on, but also serving very well as a display unit for family pictures, books and ornaments.