26 January 2017

Let there be light… again

Let there be light… again

Lights in the garden help deter intruders, so it’s a good idea to have a few set up in strategic positions to illuminate doors, windows and the darker spots of the garden.

The light set up in this instance illuminates a dark corner of the garden and also the pool – very useful if one has to check if any hapless creatures have ended up in the pool.

The issue with the original shade in this case is that it was aluminium and had become oxidised and brittle over time. The challenge was to replace it with a new fitting.

What needed to be done was to replace the fitting with a new one, but one with a different design. So this is how it was done:

- The original fitting – looking old and corroded.

- Turn the power off at the mains (unplug it for greater safety) and then remove the fitting.

- Measure across the pillar – in this case, it had an internal diameter of 75mm.

- Cut a length of 22x69mm treated timber. Cut it slightly larger and then sand it down to fit very snugly into the pillar. This was tight enough that it had to be tapped gently into the pillar.

- Align the wood with the locking-screw hole for the original fitting.

- A stainless steel wood screw was used to secure the wood in place. Hint: to check if the screw really is stainless steel, put it next to a magnet. If there is no attraction, the screw will not stick to the magnet and that will confirm it is stainless steel.

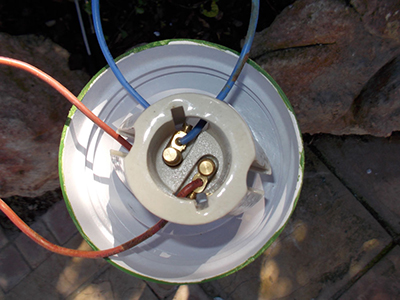

- The original fitting was earth, and though the replacement is PVC, the pillar is the original aluminium. The replacement therefore needed to be earthed as aluminium conducts electricity.

- The earth lead and wood are both secured in position with the single screw (this is where it pays off to ensure the wood is a very snug fit).

- Attach the brown and blue wires to the two plunge connectors in the bulb socket and secure the socket and the PVC shade fitting with two screws, which are driven into the wood. Now insert and secure the whole fitting.

- We applied a coat of green paint to the fitting to help it blend in better. We then inserted a new low-wattage (3W) LED globe and screwed down the bowl. Hint: Before painting the PVC fitting, sand it very lightly with 60 grit sandpaper. This roughens the surface slightly, allowing the paint to bond better. Job done.