22 August 2014

Sanding Made Easy

Effective Sanding

Orbital sanders work by moving the sandpaper in a series of very small circles so that you can achieve a great finish every time, irrespective of the direction of the wood’s grain.

Keep It Clean

To clean the sandpaper on an orbital sander, run the handle of an old plastic toothbrush across the surface; heat generated by friction causes the plastic to melt and pick up debris adhering to the paper.

Don’t Go Against The Grain

Even the slightest scratch from sanding across the grain can be difficult to remove and the wood’s fibres will tend to be lifted more as well. Always sand with the grain.

True Grit – By Degrees

The rougher the surface, the more grades of sandpaper you may need to go through. Grits range as follows:

- Coarse – 50 to 60 grit – for removing paint and sanding the roughest surfaces. Also useful when shaping.

- Medium – 80 to 100 grit – for sanding previously painted surfaces and for use at the intermediate stages of sanding, after rough sanding using 50 or 60 grit paper.

- Fine – 120 to 150 grit – for final sanding before applying a finish such as paint or varnish.

- Very fine – 160 to 240 grit – for smoothing primer or paint.

- Extra fine – 280 to 320 grit – for smoothing in between undercoats.

- Super fine – 360 to 400 grit – for wet-sanding varnish, lacquer or car body paint providing an ultra-smooth finish. Using water with this grade has the added advantage of keeping the work surface cool (vigorous sanding can generate sufficient heat through friction to cause certain finishes to start melting)

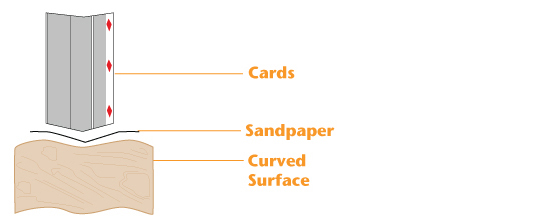

Sanding Concave Surfaces

When sanding a regular concave surface, a dowel stick of slightly lesser diameter is useful (remember to take into account the thickness of the sandpaper) To sand a complex or irregular concave surface use a pack of playing cards end on. By pressing your fingers on the top of the pack it will conform to the shape that you are sanding.

Shopping List

- Orbital Sander

- Double sided tape

- Sandpaper

- Mutton Cloth