21 August 2015

Adirondack Chair and Footrest

The Adirondack chair is an American classic and there are many variations on the Adirondack chair. Some use a series of narrower slats for the backrest, splayed out like the fingers of a hand, and others use much broader slats. We have compromised between the two, with two outer narrow slats and two centre broad slats, and it is surprisingly comfortable.

The joins are simple. You need to cut a few curved joins and a few very straight ones. Overall this chair is easier is make than you might think.

Project Guide:

TIME: 2 days

COST: R600-R750

Skill: 4

Assistant: No

Materials:

- We used meranti, stainless steel screws and fourteen 50mmx6mm gutter bolts in the construction

- 8 x 40 stainless steel screws – bag of 100

- Finish of your choice

Tools:

- Jigsaw

- Circular Cut-off Saw

- Drill

- Sander

- Cordless Screwdriver

- Belt Sander (for sanding curved surfaces such as the rear curves of the armrests and the footrest sides)

Cutting List:

- 7m of 22mm x 144mm planks

- two front legs x 520mm each

- two sides x 840 each

- two armrests x 720mm each

- two backrests x 910mm each

- one lower backrest support – 550mm cut to a radius of 715mm

- 7m of 22mmx96mm planks

- two back legs x 735mm each

- two outer backrests 670mm each

- one upper backrest support x 505mm each

- 7m of 22mmx69mm

- six seat slats x 550mm each

- six foot rest slats x 550mm each

- Two footrest sides – 22 x 22 x 500mm*

*You need only 1000m of 22mm x 22mm, but the shortest length you can usually buy is 1830mm, so try to get an offcut of just over a metre and that will be sufficient – or you will have some wastage.

*All materials are available at Selected Mica Stores. To find your nearest Mica and to enquire about availability, please go to www.mica.co.za, to use our store locator. If your local Mica does not stock exactly what you need they will be able to order or suggest an alternative product or a reputable source.

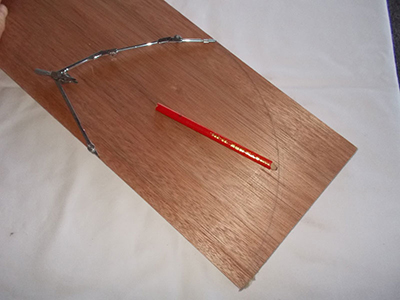

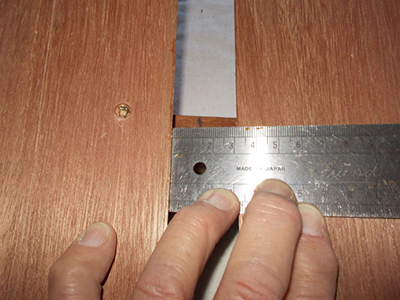

- Cut two sides from the 144mm x 22mm, each 840mm long. Round off one end of each with a compass – as shown. Then use a length of plywood or a steel rule, bent through a gentle arc to mark off the seating portion. This should have a gentle concave profile to cushion your thighs and provide a contoured profile for your… derriere.

- Once you are satisfied with the shape, use a jigsaw to cut the sides to shape. We find it best to cut one, and then use that as a template for the second side. Once both have been cut, clamp them together and sand them down for a matching profile.

- Cut the six seat slats to 550mm each and attach the first to the bottom edge of the sides, using two screws per side to secure the slat. Then position the next slat about 22mm above that. We used a couple of offcuts to keep the second slat in position and attached that as per the first slat.

- When attached to the sides, the slats make an even curve – as shown.

- Now for the legs. Cut them using a circular either a cut-off saw or jigsaw.

- Clamp the legs to the sides, 85mm from the leading edge of the side and 185mm from the foot. This should give a seat height of 360mm. This is a good height that allows the feet of the average person to rest on the ground without chaffing the back of the legs. Then drill four 6mm holes through the legs and sides.

- Attach the legs to the sides using four 6mm bolts – as shown.

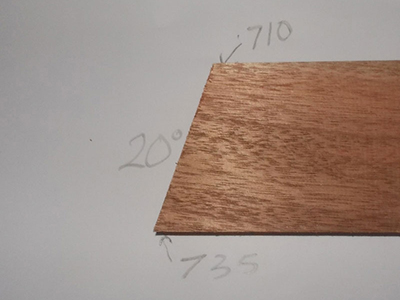

- The rear supports for the armrests and back of the seat are 735mm on the longest edge and 710mm on the shorter, giving an angle of 20°.

- These are attached 40mm in to the ends of the sides, with a single 6mm gutter bolt.

- We marked off the radius using an offcut of pegboard. We cut it with a jigsaw and attached it to the sides with two screws per side, set back 40mm on each end. This leaves room for the two outer back slats to be attached and still have a 20mm gap between them and the last of the seat slats.

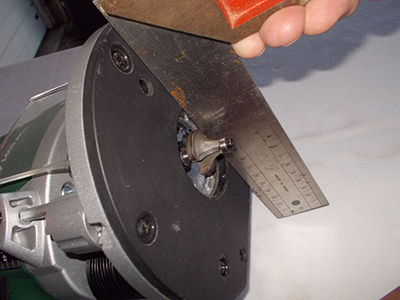

- We then cut the two armrests to 720mm each, rounded off the leading edge and gently curved the outer portions to provide a pleasing, softening curve. Each armrest was attached to the front legs with four screws per side and to the rear supports using two screws per join. We then cut the two centre slats using two lengths of 144mmx22mm at 910mm long. You’ll want to trim them to a slightly wedged shape and set the circular saw to cut to a depth of 43mm. This will cut through both slats in one pass, but not into the workbench on which you’re working; then it’s a simple case of breaking off the lower one and sanding both down.

- The lower third of the back slats were trimmed 130mm wide.

- Mark off the centre point on the two backrest supports. Then position and attach the top of the centre slats at 18mm either side of the centre point for a 36mm gap. The gap between the two slats at the bottom support should be 22mm.

- Now for the two outer slats. Cut them to length and trim them as per the two centre slats for a 66mm width where they meet the bottom support. Then mark off an arc at the top.

- Cut off the arc and sand it down for a smooth finish.

- Finally, attached each outer slat with a single screw at the top and two at the lower end.

- Now to shape the two centre slats. Mark them off as shown and cut them with the jigsaw. Now sand them down for a smooth finish.

- To provide added support to the armrests, use the offcuts from those same armrests to make braces. Attach them as shown.

- With a single screw through the leg.

- As shown here.

- Your footrest needs to be just a little below the height of the front of the seat, so measure it off. It should be 360mm.

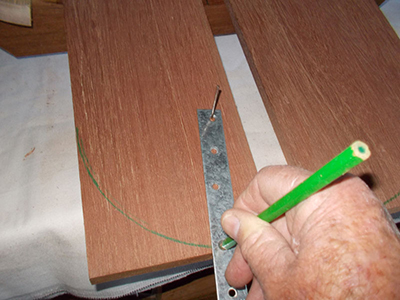

- We used a compass to mark off the leading curve of the footrest side.

- We cut the shape out with a gentle curve down towards the lower end, as shown, and used that as the template for the second side.

- We then cut the second side and clamped both sides together – as shown.

- Sand them down with a belt sander to create matching sides.

- Now for the slats. We decided to rout the edges for a more comfortable effect. First, set the router, fitted with a rounding-off bit, to the required depth to create a smooth curve.

- Run the router along the edge, moving it in about 3mm or so with each pass to avoid straining it or burning the wood.

- You might find it easiest to rout the entire length first.

- Then cutting the individual slats to length.

- Here you can see the cut slats, ready for attachment.

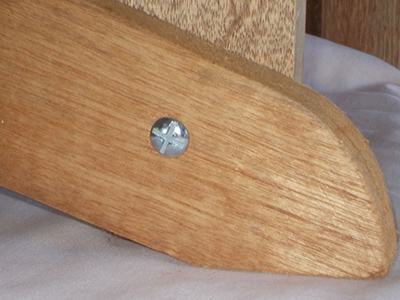

- Countersink the two screw-attachment holes per side as shown to prevent splitting the ends of the slats.

- Position the first slat at an 80mm point from the front end of the footrest and fix it in position.

- Here is the first slat attached.

- Then, spacing the rest of the slats at 22mm intervals, attach the rest in the same fashion. Use one of the slats as a spacer.

- Because the slats are attached on a curve, they provide bracing as well, making the footrest very rigid.

- Complete the footrest by adding two legs, attached as shown, to give the footrest a total height of about 350mm. Then complete the whole unit by applying the finish of your choice.

- Job done! Sit back, relax and enjoy – Top View

- Side View

- Front View

Now For The Footrest: