05 June 2023

All about drills and bits – and more: Part 5 – driver bit, shaping bits and more

The ancient Egyptians round about 3000BC gave us the bore drill, and then the Romans a couple of thousand years later brought us the auger. Then in 1895, brothers Wilhem and Carl Fein of Stuttgart, Germany gave us the first portable handheld drill and in 1889, Arthur James Arnot and William Blanch Brain of Melbourne, Australia patented the electric drill. In 1917 the first trigger-switch, pistol-grip portable drill was patented.

And things have been banging on ever since, with ever better tools, and ever better attachments – just some of which you will have seen in this series.

However, please note that this is not a complete recount of what is available; manufacturers and individuals are continually devising new accessories and new uses for these tools – so keep your eyes open for them.

Driver abbreviations

Some of the various types of drives have abbreviated or alternative names for easy identification.

Here are some examples:

- Phillips – PH

- Pozidriv (SupaDriv) – PZ

- Square socket – Robertson

- Hex socket – Allen

- Security hex socket – pin-in-hex-socket

- Torx – T & TX

- Security Torx – TR

- Triangular socket – TA

- Spanner head – pig nose – TH

- Clutch – A & G

- Triple square – XZN

Caution

We are going to repeat this, but if you have not already done so, adopt the habit of wearing eye protection when using tools – even hand tools. But in the context of this series, and in particular, when removing paint and/or rust from surfaces, protect your eyes – they are the ONLY ones you’ve got!

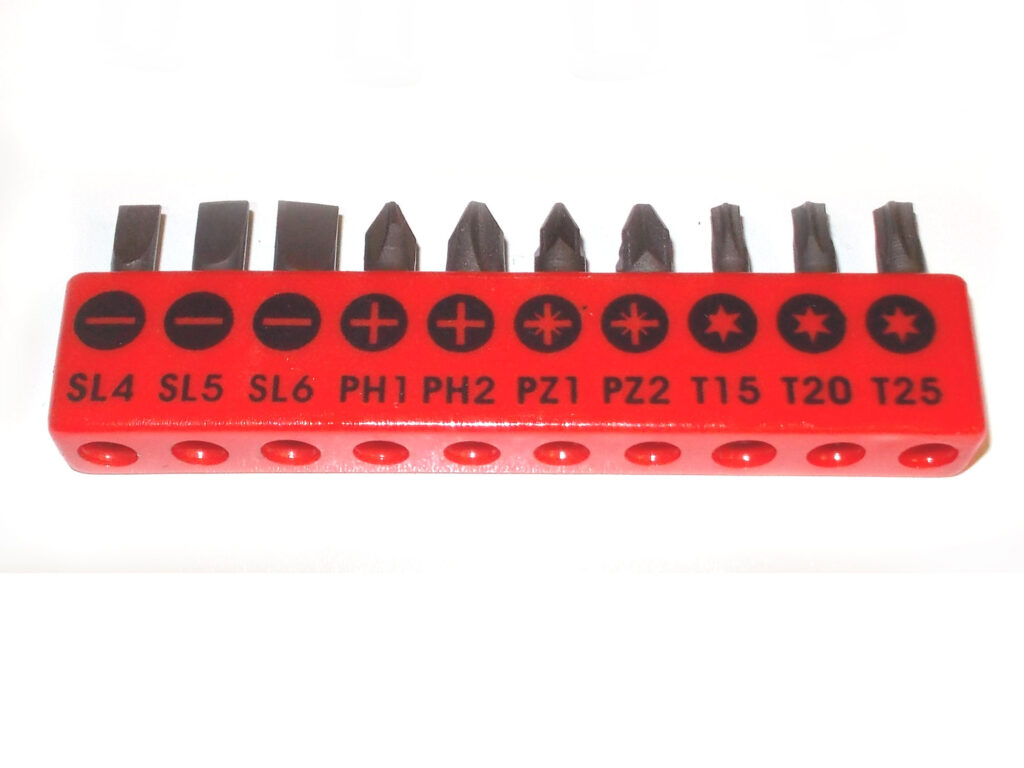

- First we will look at a variety of bits designed for working with screws. This set (L-R) comprises three slot (or flat), two Phillips, two Pozi and three Torx. They are all 6.24mm hex shanks.

- A smaller set, comprising two slot, two Phillips and two Pozidriv heads

- This is set comprises four hex heads, two Pozi, two Phillips and two slot heads.

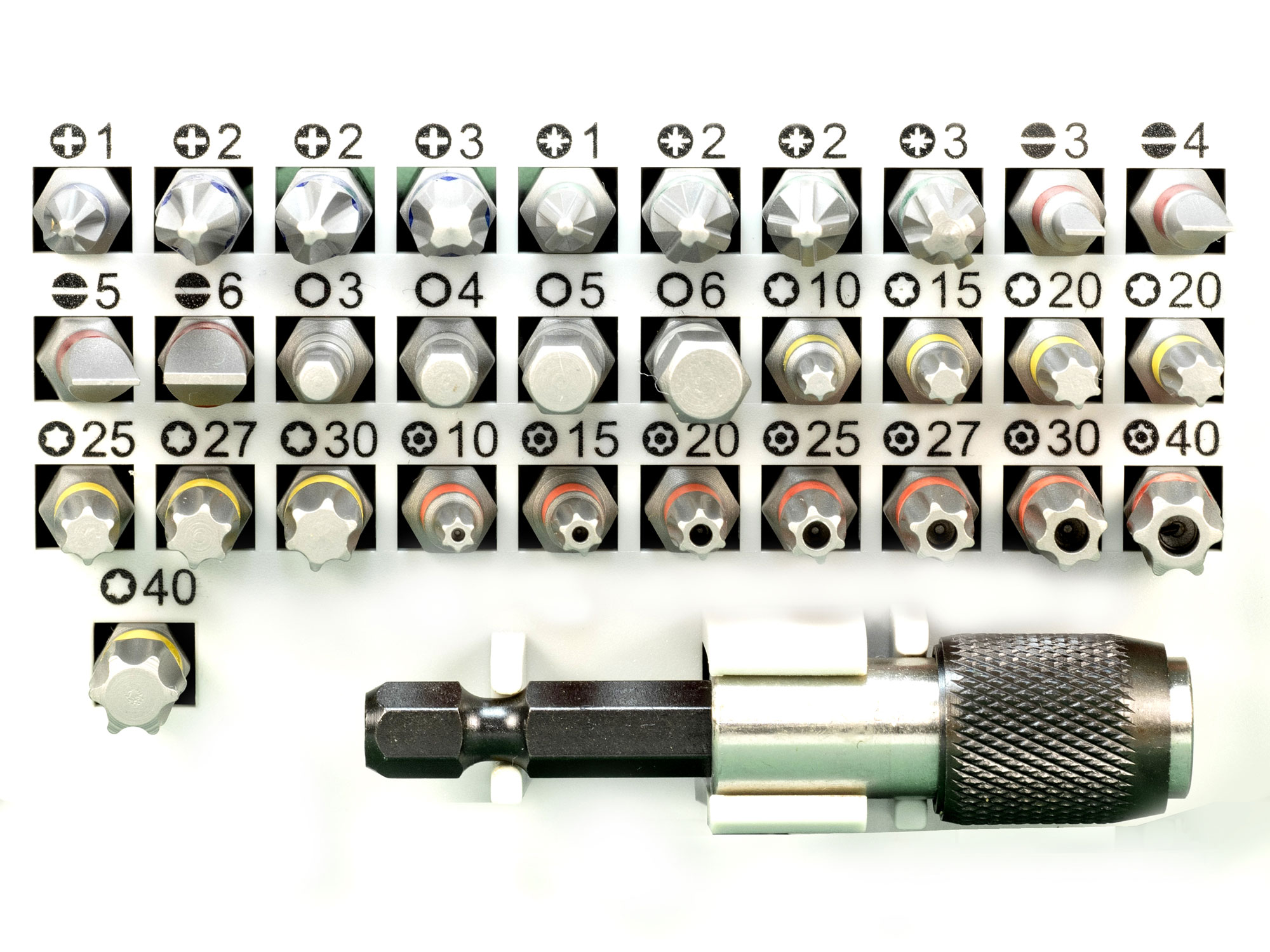

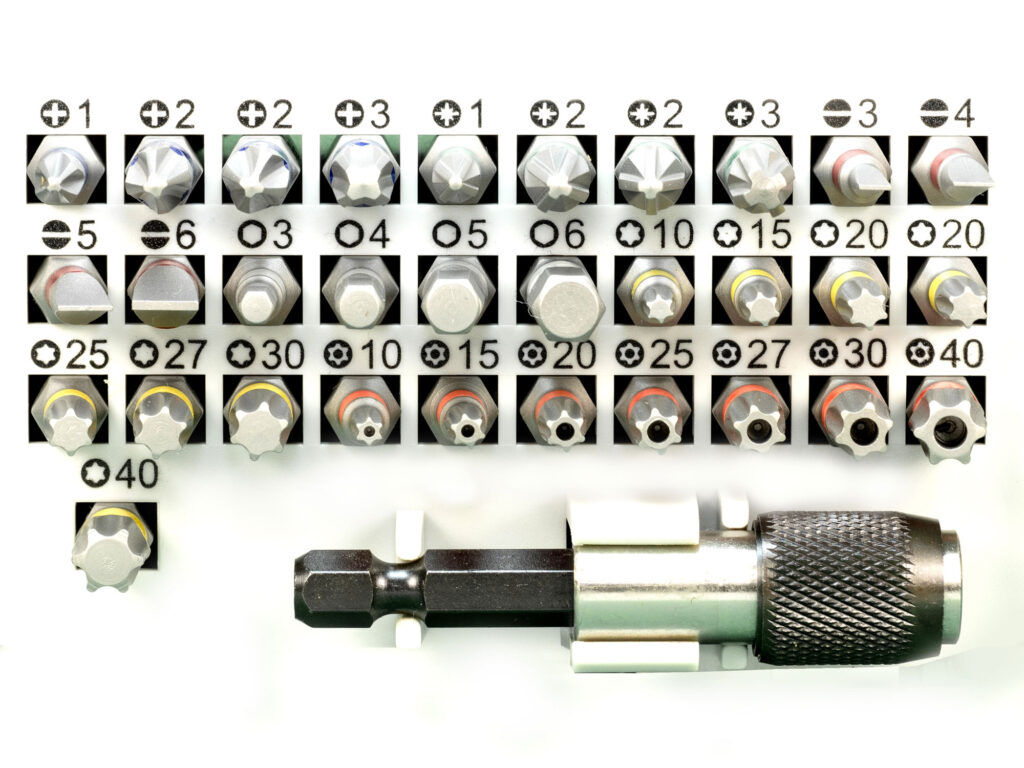

- A far larger set which in this case included security heads – they are the ones with a hole down the centre. Security hex and security Torx heads have a small protrusion in the centre of the recess in the screw head. This prevents a standard hex or Torx drive being inserted into the recess. In these cases, a security head of the correct type is used. The hole in the drive passes over the protrusion in the screw head, fully seating in the drive and allowing the fastener to be turned. The holder at the bottom of the set allows for the quick-change of bits as required.

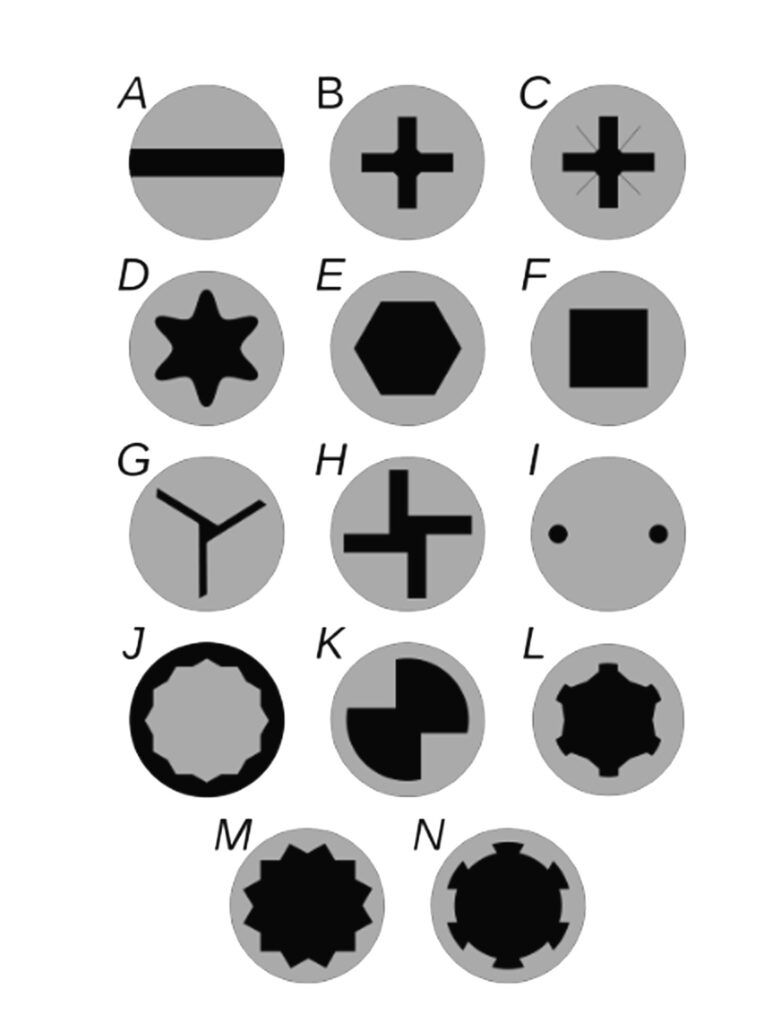

- Screw drives: There are many screw drives but here we are going to deal with just those that you might come across during your work at your Mica store. A – Slot – requires a Flat Tip; B – Phillips; C – Pozi; D – Torx; E – Hex Socket; F – Robertson or Square; G – Tri-Wing; H – Torq-Set; I – Spanner Head; J – Spline Drive; K – One Way; L – Poly Drive; M – Triple Square; N – Bristol.

- A set of 50mm bits, which allow the user to drive in or remove deeply bedded screws or any that have obstructions near them.

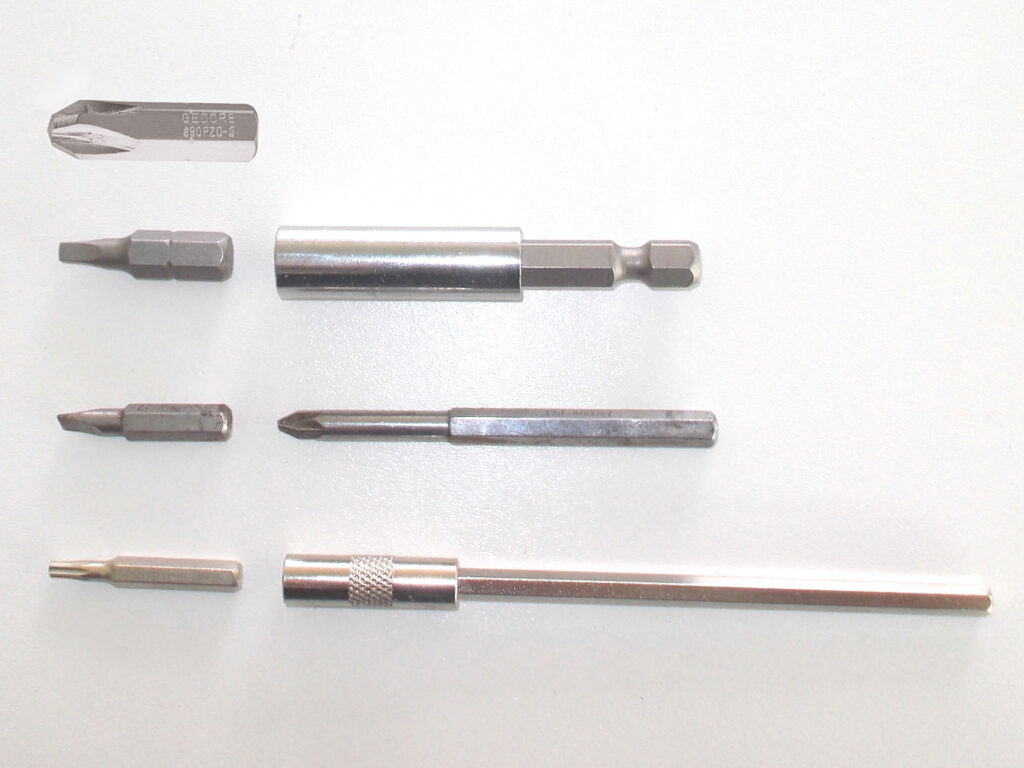

- This image shows a variety of bit lengths – 25mm, 50mm and 150mm, plus (top right) a magnetic socket drive.

- A note about hex shank sizes: Hex shank sizes vary and are measured across the flats – in other words, from one flat face to the parallel flat face directly opposite. In this image the 9.25mm (3/8 inch) bit at the top is used in conjunction with an impact screwdriver. The 6.25mm (1/4 inch) (second from the top) is the most common size and used in a wide variety of applications – screwdriver bits, and various drill bits, for example, while the smaller versions at the bottom of the image are usually on the packaging shown as 4.74mm (3/16 inch), and are used for very fine work, for example being used with bits with flat tips down to 1.5mm or so.

- A large set of 4.74mm bits. These are intended for use for very fine work and are not recommended for use with power tools, which could exert too much force on them. Rather use them with the good old Mark 1 Human Hand.

- This image shows the difference between Phillips head and drive on the left, and the Pozidriv and head on the right. Note that the Phillips tangs have a slight taper, which means that they can rise up and disengage with the screw head, whereas the Pozidriv tangs are parallel. In short, Pozidriv screwdrivers can be jam-fitted into Phillips screws, but may slip or tear out the Phillips screw head when tightened. Phillips screwdrivers, on the other hand, will loosely fit and turn Pozidriv screws but if enough torque is applied will cam out, possibly damaging the screw head or screwdriver, or leaving the screw head altogether and damaging the surrounding surface.

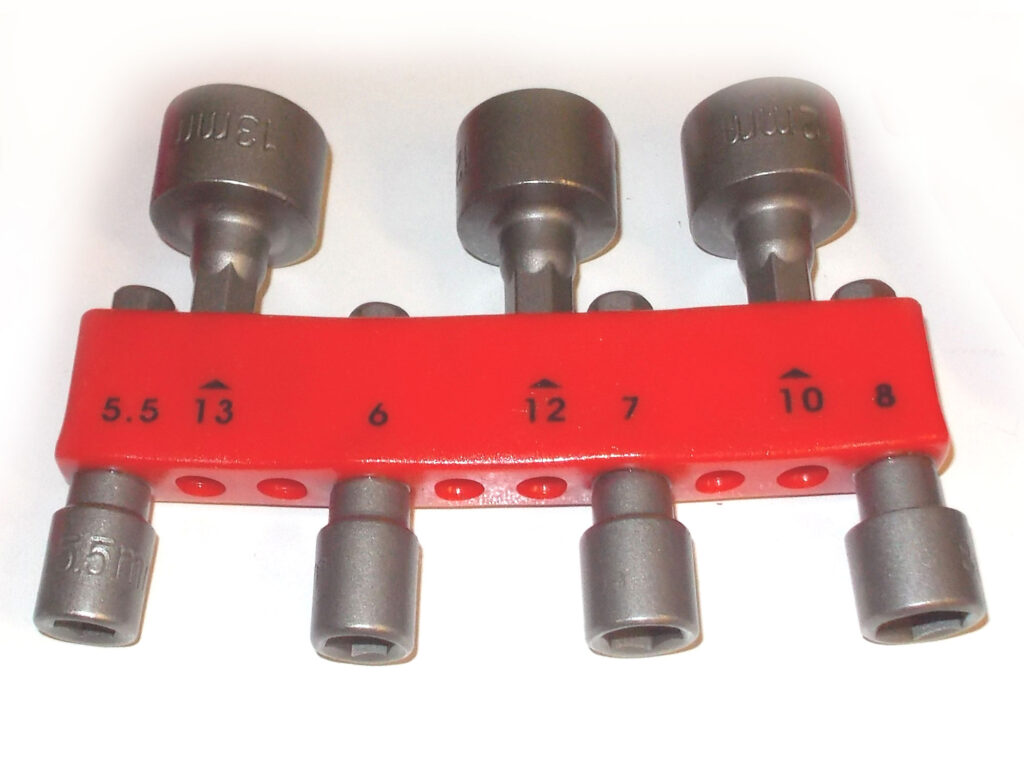

- A set of seven nutsetters. These are power tool accessories designed to fasten metal and self-tapping screws. Shown here is a small set. The bottom row (L-R) 5.5mm, 6mm, 7mm and 8mm, with (R-L) 10mm, 12mm and 13mm at the top.

- A set of countersink bits – 8mm, 12mm, 16mm and 19mm plus a magnetic bit holder 60mm long. Again, the latter allows for a quick change between countersinking the screw hole and then substituting the countersink bit for the driver bit.

- Shaping bits – rotary files – for use only on mild steel or other softer metals such as aluminium and alloys, though on some metals you might experience a little binding… when the bit grips the metal. The secret is a light touch. They can be used for smoothing metal. Shown here are ball, cylindrical and tapered V point.

- Examples of grindstones, suitable for use on metals such as aluminium, zinc, copper and steel. Note that in some cases a maximum of 25000rpm is recommended.

- These are rotary rasps, but intended for use on wood ONLY. They are NOT suitable for working on metal. Shown here are two examples of cylindrical and one round end rasp. You could possibly use these on PVC as well, but beware of the material melting due to friction and then having to be picked out of the teeth.

- Two examples of drill saws – a 6mmØ and 8mmØ for use on metals and can also be used on PVC.

- Four examples of plug cutters – shown here are 6mmØ, 8mmØ, 10mmØ and 12mmØ. As their name implies, plug cutters are designed to cut very precise plugs to be inserted into a screw hole, to hide the heads of the latter, when the latter is at the bottom of a hold drilled using a spade bit, for instance. It is a good idea when cutting plugs to select parts of the wood from which the plugs will be cut, to match area and grain as much as possible and then when gluing the plugs into position, aligning the direction of the grain as precisely as possible.

- Some more examples of plug cutters, in this case 6mmØ, 8mmØ, 12mmØ, 13mmØ and 25mmØ. Also available is a 10mmØ plug cutter.

- Three examples of multi-angle drill bits, in this case 15mmØ, 16mmØ and 19mmØ. They are used for drilling, edge-drilling, routing, channelling and milling wood. Note the individual bits may have different recommended speeds. In this case the 15mmØ version has recommended speeds of 2400rpm when used on soft woods and 500rpm when used on hard woods, whereas the 19mmØ version has recommended speeds of 1500rpm in soft woods and the same 500rpm in hard woods. The 16mmØ version does not appear to carry any information in this regards, but for safety it is probably as well to follow the lower limit of the 15mm version.

- SAFETY FIRST! You have just one pair of eyes so protect them. If nothing else, welder’s goggles (with flip-up dark glass lenses so you flip them up for a clear view) will work.

- Ideally, since we would (or should) have bought facemasks and/or safety glasses during the pandemic, try them. It is best that the safety glasses are wrap-around, so no particles of paint, metal or other residue can get into your eyes from the sides, should they bounce off a nearby surface. And yes, it can happen!

- Safety is particularly important when using wire brushes – in this case brass-bristled – to remove rust and old paint. It is little comfort that steel-bristled brushes, should a bristle come loose, can be removed from your eye possibly using a very strong magnet wielded by your newly acquainted eye specialist,. That is not the case with a brass bristle. Either way, whatever bristle or piece of debris gets in your eye or eyes could be extremely distressing and even life-changing. Note in this image that these fittings also advise wearing eye protection, and in addition, recommend a maximum speed of 4500rpm. Follow both instructions.

- This 100mmØ abrasive disk uses nylon bristles to do the job at a maximum of 4500rpm and is designed for use on wood, plastics and metals – for example for removing burrs on steel, stainless steel and aluminium, rust and so on. It has a milder touch than it brass or steel-bristled cousins.

And that is it. Remember, new products are coming along all the time, so keep checking out your local Mica for whatever you need, and if you have a new task you need to do, ask your local Mica for advice.

Panel:

Mica Stores carry a range of power drills, hand drills and bits and accessories. To find your closest Mica and whether or not they stock the items required, please go to www.mica.co.za, find your store and call them. If your local Mica does not stock exactly what you need they will be able to order it for you or suggest an alternative product or a reputable source.