21 December 2020

No more washing-day moving blues

The laundry hamper (perhaps also known as laundry bin or laundry box) shown here is a very good one – and very heavy, particularly when loaded. It is also quite large and so it is not kept right next to the washing machine. However, it is nice to be able to move it to the machine when necessary, and then back to its nesting position for the rest of the time.

The solution was to add casters.

Materials:

- Four 40mmØ swivelling casters (nylon)*

- MDF – One 16mm sheet, 600x600mm

- 16mm chipboard screws

- Wood glue

- Finish of your choice – I used gloss varnish

Later on I then used…

- Meranti – one 1.83m length of cover strip 9x44mm

*Casters with black rubber wheels are also available but I used the nylon wheel version as there is no risk of marking the carpet or any other surface.

Method:

- The feet of the laundry hamper make it quite difficult to move about.

- The easiest method of attaching casters is to attach them directly to the feet, but these feet have been bevelled and are hence too small for any suitable caster baseplate. There are casters with a single shaft insert (or bolt) but the trouble is that when the hamper is fully loaded it is rather heavy and the off-set load exerted by a caster could cause the foot to split.

- So… I decided to make a flat trolley to which the casters would be attached and on which the feet would rest. The first step is to measure the dimensions, and then add about 4mm to ensure the trolley fully supports the feet.

- These casters are capable of bearing the weight of the hamper when it is loaded. Also shown here are their attachment screws.

- Measure off the trolley base on the sheet of MDF.

- Then cut the base to size.

- With the hamper upside-down, check that the base fits properly. It needs to be just a little larger, as said by about 2mm on each edge – the above-mentioned 4mm refers – so that the feet sit squarely on the base.

- With the base properly centred, mark off the position of the feet.

- Then cut edging pieces from the leftover MDF so that each piece fits between the legs. Many Mica stores offer a free cutting service, and you can take advantage of it, but ensure that whatever cutting instructions you give, are exactly what you need… once the wood is cut, it’s yours… knots, wrong sizes and all!

- The edging pieces are glued in position.

- To reinforce the union, I secured each strip with three screws.

- With the hamper still inverted, I checked the trolley base fits properly. It does!

- Now I attached a caster at each corner as shown here.

- Should you use slightly overlong screws and their tips protrude…

- The solution is simple… drive them in (to cut their thread in the wood), then remove them and snip off the excess then drive them back in again to finally secure the caster.

- I could have driven longer screws right through the trolley base and secured it to the underside of the hamper, but I decided to use cord instead… that makes it easier to detach the trolley when necessary to retrieve any coins or whatever than might fall out of pockets and into the trolley.

- The inner view.

- Job done… but then…

- I thought the trolley looked a bit unfinished, so I removed it and got hold of the meranti cover strip.

- I secured supports to the underside of the trolley – note the use of 250 micron black plastic sheet to stop glue sticking the support to the underside of the trolley.

- Make sure that the support is absolutely flat against the underside of the trolley – so it needs to avoid the caster’s base.

- I mitred one end of the cover strip and aligned it with the corner of the trolley as shown here.

- Then I marked off and mitred the other end, and applied glue. And clamped it in position, resting on the supports… this makes it easy to ensure that the bottom edge of the strip is exactly flush with the bottom edge of the trolley base.

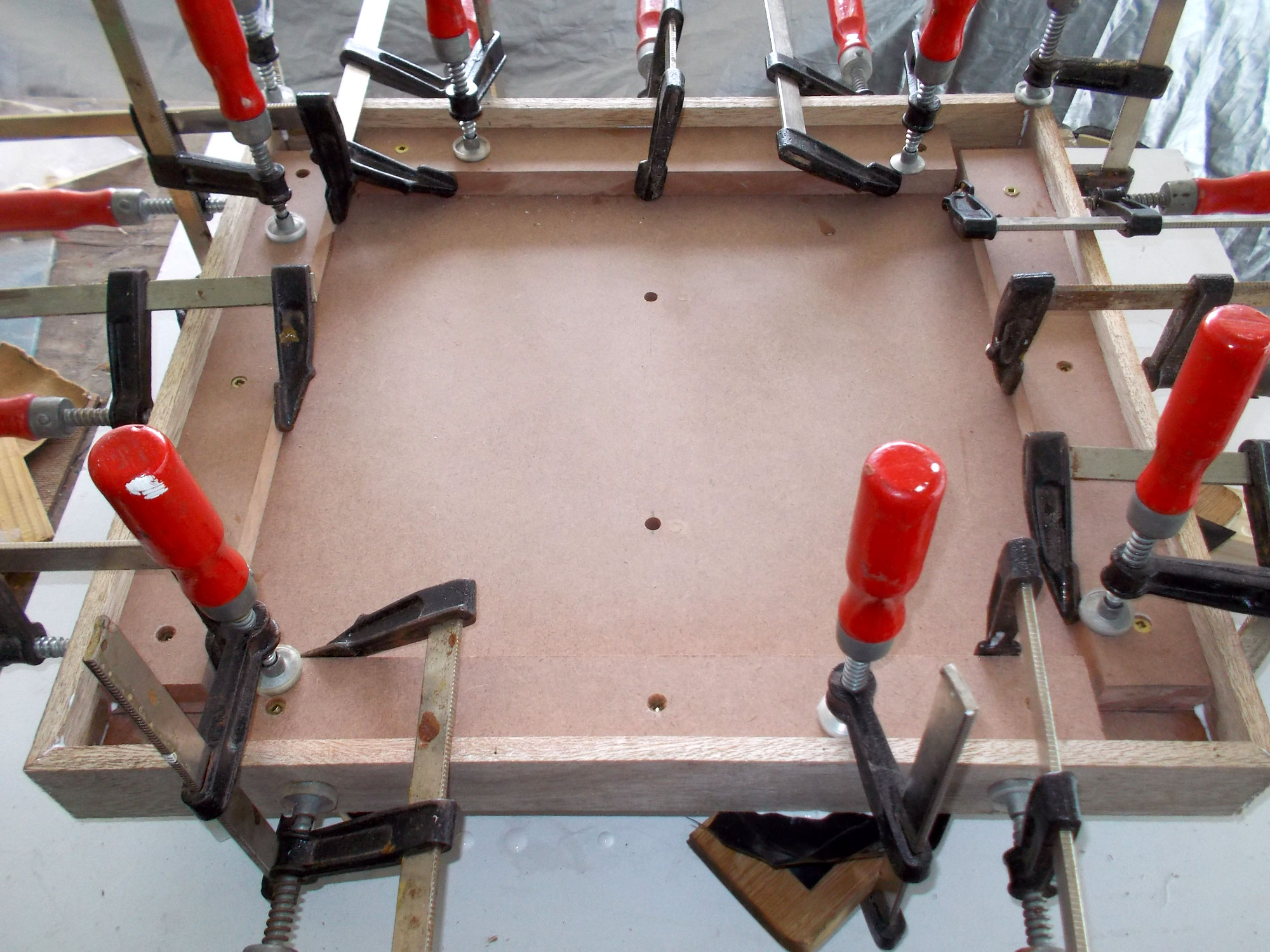

- With the cover strip clamped into position, I cut and fitted the second strip – you should aim for the neatest mitred corner that you can, obviously. I repeated the procedure until all for sides had their cover strips attached.

- To ensure exact alignment, I also clamped each corner as shown here.

- Like money and health, you can NEVER have too many clamps!

- Once the glue had cured, I sanded each side.

- Prior to applying the varnish finish, I masked off the casters.

- I then applied varnish to the edging, and also to the trolley base as MDF does not take kindly to moisture (it’s rather like chipboard in its dislike of water), so it needs to be sealed in case a soaking wet swimming costume ends up in the hamper and water drips on to the trolley.

- The meranti was not quite the colour I wanted, but I think you will agree the final result is better than the bare MDF trolley surfaces of the original.

- The completed job…now the laundry hamper is easily moved to where needed.

Note:

I always find it best to pre-sand the various pieces before I assemble any unit, with a final fine sanding just before applying the finish, and in this case, paint the frame and feet before attaching the panel and completing the project… it just makes thing a whole lot easier.

Panel:

These materials are available at Selected Mica Stores. To find your closest Mica and whether or not they stock the items required, please go to www.mica.co.za, find your store and call them. If your local Mica does not stock exactly what you need they will be able to order it for you or suggest an alternative product or a reputable source.

Project guide

TIME: 2-3 hours (allowing time for the glue to cure

COST: R80

Skill: 4

Assistant: No

Tools required:

Jigsaw or mitre saw, sander – random orbital or orbital.